EDO Specialty Plastics Inc is a leading manufacturer of custom plastic extrusions for more than 60 years. The company has a strong reputation for providing high-quality products, exceptional customer service, and innovative solutions to meet the needs of its customers.

Custom plastic extrusions are made by melting raw plastic material and then forcing it through a die to create a specific shape or profile. This process allows for the creation of complex shapes that cannot be produced using traditional molding techniques. EDO Specialty Plastics Inc specializes in creating custom plastic extrusions that meet the unique needs of its customers.

EDO Specialty Plastics Inc offers a wide range of products to meet the needs of various industries. Some of the products offered by the company include:

1. Experience: With over six decades in business, EDO Specialty Plastics Inc has extensive experience in creating custom plastic extrusions.

2. Quality: The company's commitment to quality is evident in its ISO 9001:2015 certification and rigorous testing procedures.

3. Customization: EDO Specialty Plastics Inc works closely with its customers to create custom plastic extrusions that meet their unique needs and specifications.

4. Competitive Pricing: The company offers competitive pricing without compromising on quality.

Custom plastic extrusions offer several benefits, including:

Custom plastic extrusions can be used in a wide range of industries, including but not limited to:

If you're looking for a reliable manufacturer of custom plastic extrusions, look no further than EDO Specialty Plastics Inc. With years of experience, dedication to quality, customization options, competitive pricing, and exceptional customer service, the company is well-equipped to meet your needs. Contact them today to learn more about their products and services.

EDO Mtech Inc. Pennsylvania. EDO Professional Services, Inc. Virginia ... Specialty Plastics Inc. Louisiana. Electronic Systems Division. n/a. Geospatial ... U.S. Securities and Exchange Commission Your Request Originates from an Undeclared Automated Tool To allow for equitable access to all users, SEC reserves the right to limit requests originating from undeclared automated tools. Your request has been identified as part of a network of automated tools outside of the acceptable policy and will be managed until action is taken to declare your traffic. Please declare your traffic by updating your user agent to include company specific information. For best practices on efficiently downloading information from SEC.gov, including the latest EDGAR filings, visit sec.gov/developer. You can also sign up for email updates on the SEC open data program, including best practices that make it more efficient to download data, and SEC.gov enhancements that may impact scripted downloading processes. For more information, contact opendata@sec.gov. For more information, please see the SEC’s Web Site Privacy and Security Policy. Thank you for your interest in the U.S. Securities and Exchange Commission. Reference ID: 0.4d8a1402.1728585084.24bfee0 By using this site, you are agreeing to security monitoring and auditing. For security purposes, and to ensure that the public service remains available to users, this government computer system employs programs to monitor network traffic to identify unauthorized attempts to upload or change information or to otherwise cause damage, including attempts to deny service to users. Unauthorized attempts to upload information and/or change information on any portion of this site are strictly prohibited and are subject to prosecution under the Computer Fraud and Abuse Act of 1986 and the National Information Infrastructure Protection Act of 1996 (see Title 18 U.S.C. §§ 1001 and 1030).

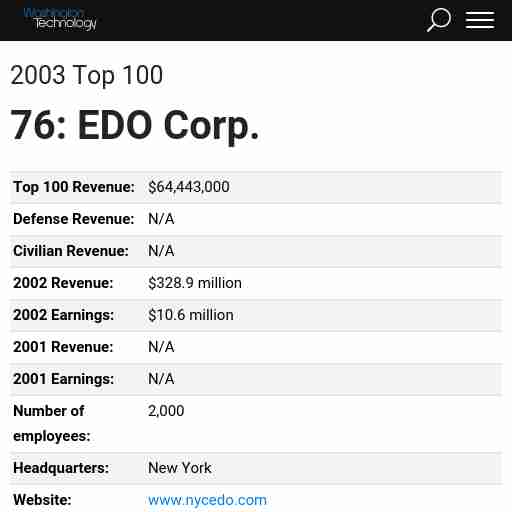

76: EDO Corp. Top 100 Revenue: $64,443,000. Defense Revenue: N/A. Civilian ... products, specialty plastics and technical services operations. Major ... James Smith, chairman, president and CEO Lines of business: Advanced engineering and research, nucleonics, antenna products and technologies, combat systems, communications and countermeasures systems, defense programs and technologies, electro-ceramic products, fiber science, marine and aircraft systems, professional services, reconnaissance and surveillance systems, space and communications products, specialty plastics and technical services operations Major customers: Navy and Air Force Major contracts/projects: EDO has provided support services to the Marine Corps Warfighting Laboratory since 1995. Services including helping the lab with developing tactics, techniques and procedures, and evaluating advanced technologies that create or enhance future Marine Corps warfighting capabilities. These tactics, techniques, procedures, and advanced technologies are then integrated into the Marine Corps Combat Development Command system for procurement or implementation. Insider Customer Service 800-353-9118 or email washingtontechnology@omeda.com © 2024 by Government Media Executive Group LLC. All rights reserved.

Future Pipe Industries is a leader in composite piping solutions. We design and manufacture composite piping solutions for use across the Oil & Gas, Industrial, Water, and Marine & Offshore Industries. Our solutions include piping system design, manufacturing, engineering services, project management, technical support, field supervision, and training. Learn more about our composite pipe solutions Composite piping solutions create value for applications across a wide range of industry sectors. Composite pipes offer excellent resistance against corrosive environments including soils, hydrocarbons, salt water, H2S, and chemical compounds typically encountered in any oil field. Composite pipes are exceptionally durable, making them an excellent choice as they create value in a world of ever-increasing energy demand. Composite pipes accommodate a variety of assembly options and complex configurations in the Industrial sector due to their versatility and capacity to withstand high pressures, temperatures, and loads, as well as their excellent chemical resistance. Safe, reliable, and long-lasting makes composite pipes a natural choice for the water industry. They provide a better hydraulic performance than steel, ductile iron, and concrete, meaning projects can benefit from significantly reduced Operating Expenses. Onshore projects are becoming more demanding for higher sizes and pressures leading to bulkier products. As offshore exploration goes into deeper water, platform weights become prohibitive.Composite pipes are 75% lighter than steel, by deploying of composites in as many service applications as possible, weights can be reduced, allowing for faster installation and the use of lighter construction equipment.

... sector includes six business units: Defense Systems, EDO (UK) Ltd., Fiber Innovations, Fiber Science, MTech & Artisan, and Specialty Plastics. From Wikipedia, the free encyclopedia hideThis article has multiple issues. Please help improve it or discuss these issues on the talk page. (Learn how and when to remove these template messages) This article may be unbalanced towards certain viewpoints. (July 2010) This article needs additional citations for verification. (December 2020) Predecessor Edo Aircraft Corporation Fate Acquired by Harris Corporation Revenue $715 million USD (2006) EDO Corporation was an American company which was acquired by ITT Corporation in 2007. EDO designed and manufactured products for defense, intelligence, and commercial markets, and provided related engineering and professional services. It employed 4,000 people worldwide and had revenues of $715 million in 2006. EDO's assets went to ITT Defense Electronics and Services. As of May 2015, these assets were now part of Harris Corporation,[1] and since June 2019 L3Harris Technologies.[2] Earl Dodge Osborn founded the Edo Aircraft Corporation in 1925. The company's first successful product line was pontoons for floatplanes. With the outbreak of World War II, the company's focus shifted, and EDO began to provide subassemblies for military aircraft. This shift in emphasis led to the company being renamed the EDO Corporation in November 1947. EDO became a public company in 1956 with its listing on the American Stock Exchange, and moved to the New York Stock Exchange in 1983. An agreement was reached September 18, 2007 for ITT Corporation to buy EDO for $1.7 billion.[3] After EDO shareholders' approval, the deal was closed and finalized on December 20, 2007.

Green Leaf Inc.Flowserve Corp.EDO Specialty PlasticsVictaulicIPEX USA LLCDormont Mfg. Co.Integra Dynamics Inc.Vinyltech PVC PipeStrahman Valves, Inc.Keeney Mfg. Building Product Divisions > 23 - Heating, Ventilating, and Air Conditioning (HVAC) > 23 05 00 - Common Work Results for HVAC 23 05 00 - Common Work Results for HVAC Manufacturers of Common Work Results for HVAC Browse companies that make common work results for hvac and view and download their free cad drawing, revit BIM files, specifications and other content relating to common work results for hvac as well as other product information formatted for the architectural community. CV-FLG-RD Swing Check Valve, EPV Eccentric Plug Valve, GV-FXF-NRS Flanged by Flanged NRS Gate Valve... CAD BIM SPECS CATALOGS PRODUCTS CAD SPECS CATALOGS VIDEOS PRODUCTS DATASHEETS MediTrac® Corrugated Medical Tubing (CMT), TracPipe® Counterstrike® Natural Gas and LP Piping System... Pipe Identification for HVAC, Plumbing and Electrical, Pipe, Cable & Conduit Markers, Snap-Around Identification Markers... SPECS CATALOGS VIDEOS LEED PRODUCTS SPECS CATALOGS VIDEOS LEED PRODUCTS Soffi-Steel® Concealment System, JGI Interlock™ Concealment Systems, ALumA-Fit™ Concealment System... CertainTeed Corp., Insulation Group Flowline Div. Markovitz Enterprises Soffi-Steel / Grice Engineering INNERFACE Architectural Signage, Inc. Plumberex Specialty Products, Inc. Advanced Support Products, Inc. Rhino Marking and Protection Systems United Fiberglass of America, Inc. Caddy Mechanical, Division of Erico, Inc. Silverback Solar, a RoofScreen Mfg., Inc. Company Panasonic Life Solutions Company of America Toro Company- Irrigation Division